Energy Dispersive X-Ray Spectroscopy (EDS) Analysis Laboratory

Energy Dispersive Spectroscopy (EDS Analysis) is used in conjunction with the Scanning Electron Microscope (SEM) providing chemical analysis in areas as small as 1 µm in diameter. EDS detects all elements except for H, He, Li, and Be. EDS can be performed exactly on any features or particles seen in the SEM images and can “MAP” elements on a surface. Unknown materials can be identified and quantitative analysis can be performed.

Energy Dispersive Spectroscopy (EDS)

EDS, also called Energy Dispersive X-ray Spectroscopy (EDX), is a technique based on the collection and energy dispersion of X-rays created when high energy electrons bombard a sample. The EDS is attached to the Scanning Electron Microscope (SEM) and the two techniques are often used together. The X-rays have energies that are characteristic of the elements in the sample.

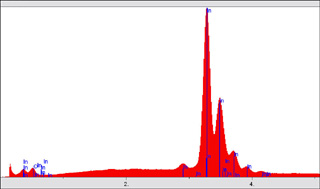

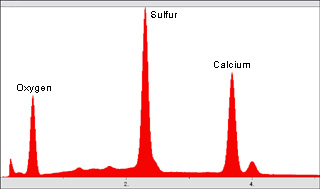

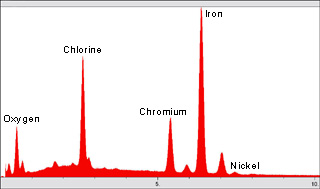

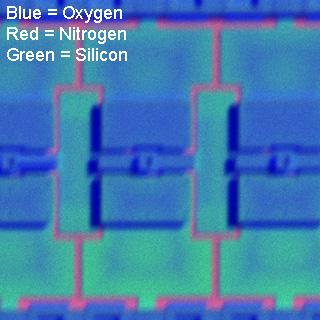

The instrument’s electronics process the signals to give histograms of energy vs. signal strength, the latter being related to relative concentration. EDS Analysis can also provide elemental maps of the sample that can be compared to the electron micrographs. The method detects all elements from boron to uranium and is usually nondestructive. Detection limits range from 0.05-2% for high to low Z elements, respectively. Features as small as 1 µm. EDS is particularly good for relating elemental composition to topographical features.

How does Energy Dispersive X-Ray Spectroscopy (EDS) Analysis work?

Energy Dispersive X-ray Spectroscopy (EDS) Analysis works by measuring the energy of X-rays emitted by a sample when it is bombarded with high-energy electrons or X-rays. Here is a step-by-step overview of how EDS analysis works:

- A sample is prepared by coating it with a thin layer of conductive material to prevent the buildup of electrostatic charge. The sample is then placed in a vacuum chamber to prevent the X-rays from being absorbed by air.

- The sample is bombarded with a beam of high-energy electrons or X-rays, which excites the atoms in the sample, causing them to emit X-rays of characteristic energies.

- The emitted X-rays are then collected by a detector, which is typically a solid-state detector made of a material such as silicon or germanium. The detector converts the X-rays into electrical signals, which are then analyzed by a computer.

- The computer then calculates the energy of the X-rays and identifies the elements present in the sample based on their characteristic X-ray energies. The computer generates a spectrum of the X-ray energies detected, which can be used to determine the elemental composition of the sample.

- The elemental composition of the sample can be visualized using a mapping technique called elemental mapping, which shows the spatial distribution of elements in the sample.

Energy Dispersive X-Ray Spectroscopy (EDS) Analysis Process

The process of conducting an Energy Dispersive X-ray Spectroscopy (EDS) analysis involves the following steps:

- Sample Preparation: The sample to be analyzed is prepared by mounting it on a conductive substrate, such as a carbon tape or metal grid. The sample must be conductive or coated with a conductive layer to prevent charging during the analysis.

- Analysis Setup: The sample is placed in a vacuum chamber, which is necessary to avoid the scattering or absorption of X-rays by air molecules. A high-energy electron or X-ray beam is directed at the sample to excite the atoms in the sample.

- X-ray Emission: The high-energy electrons or X-rays cause the atoms in the sample to emit characteristic X-rays. These X-rays are unique to each element and have a specific energy level, allowing the detection and identification of elements present in the sample.

- X-ray Detection: The emitted X-rays are detected by a solid-state detector made of silicon or germanium. The detector converts the X-rays into electrical signals, which are then amplified and processed by a computer.

- Spectrum Generation: The computer analyzes the energy of the X-rays detected by the detector and generates a spectrum of the X-ray energies. The spectrum shows the intensity of the X-rays detected at each energy level, which can be used to identify the elements present in the sample.

- Elemental Mapping: Elemental mapping can be used to visualize the spatial distribution of elements in the sample. This is done by collecting a series of spectra while scanning the electron or X-ray beam across the sample. The spectra are then used to generate an elemental map, which shows the distribution of elements across the sample.

Principles of Energy Dispersive X-Ray Spectroscopy (EDS) Analysis

The principles of Energy Dispersive X-ray Spectroscopy (EDS) Analysis are based on the interaction of high-energy electrons or X-rays with the atoms of a sample. When a sample is bombarded with high-energy electrons or X-rays, the atoms in the sample become excited and emit X-rays of characteristic energies. These X-rays can then be detected and analyzed to determine the elemental composition of the sample.

The energy of the X-rays emitted by the sample is directly related to the atomic number of the element emitting them. Each element emits a unique set of X-rays with specific energies, which can be used to identify the elements present in the sample. The intensity of the X-rays emitted by each element is proportional to the concentration of the element in the sample.

The detection and analysis of X-rays emitted by the sample require specialized equipment, including a solid-state detector made of a material such as silicon or germanium. The detector converts the X-rays into electrical signals, which are then analyzed by a computer. The computer calculates the energy of the X-rays and identifies the elements present in the sample based on their characteristic X-ray energies.

Energy Dispersive X-Ray Spectroscopy (EDS) Analysis Laboratory can provide valuable information on the elemental composition of a wide range of materials, including metals, minerals, ceramics, polymers, and biological materials. It is a powerful tool for materials characterization and is widely used in materials science, metallurgy, geology, and environmental science, among other fields.

Applications of Energy Dispersive X-Ray Spectroscopy (EDS) Analysis

Energy Dispersive X-ray Spectroscopy (EDS) analysis has a wide range of applications in materials science, engineering, geology, and other fields. Some of the most common applications of EDS analysis include:

- Materials characterization: EDS analysis is commonly used to determine the elemental composition of materials, including metals, minerals, ceramics, polymers, and biological materials. It is used to identify unknown materials, determine their purity, and quantify the concentrations of elements in a sample.

- Failure analysis: EDS analysis is often used to investigate the causes of material failure, such as corrosion, wear, and fracture. By analyzing the elemental composition of a failed component, engineers can determine the mechanisms that led to its failure and develop strategies to prevent similar failures in the future.

- Semiconductor analysis: EDS analysis is used in the semiconductor industry to determine the elemental composition of thin films, identify defects in semiconductor materials, and measure the thickness of layers in electronic devices.

Where is Energy Dispersive X-Ray Spectroscopy (EDS) Analysis used?

Energy Dispersive X-ray Spectroscopy (EDS) analysis is used in a wide range of fields and industries where the elemental composition of materials needs to be determined. Some of the most common areas where EDS analysis is used include:

- Materials Science: EDS analysis is widely used in materials science to analyze the composition of various materials, such as metals, ceramics, polymers, and semiconductors.

- Metallurgy: EDS analysis is commonly used in metallurgy to analyze the composition of metals and alloys, including the identification of trace elements and impurities.

- Semiconductor Industry: EDS analysis is used in the semiconductor industry to determine the elemental composition of thin films, identify defects in semiconductor materials, and measure the thickness of layers in electronic devices.

Industries which need Energy Dispersive X-Ray Spectroscopy (EDS) Analysis

Energy Dispersive X-ray Spectroscopy (EDS) analysis is used in various industries that require the analysis of the elemental composition of materials. Some of the industries where EDS analysis is commonly used include:

- Materials Science: EDS analysis is widely used in materials science to study the composition of various materials, including metals, ceramics, polymers, and semiconductors.

- Metallurgy: EDS analysis is used in metallurgy to analyze the composition of metals and alloys, including the identification of trace elements and impurities.

- Semiconductor Industry: EDS analysis is used in the semiconductor industry to determine the elemental composition of thin films, identify defects in semiconductor materials, and measure the thickness of layers in electronic devices.

- Automotive Industry: EDS analysis is used in the automotive industry to analyze the composition of materials used in manufacturing, such as metals and polymers.

- Aerospace Industry: EDS analysis is used in the aerospace industry to analyze the composition of materials used in aircraft manufacturing, including metals and composites.

Strengths and Limitations Energy Dispersive X-Ray Spectroscopy (EDS) Analysis

Strengths of Energy Dispersive X-ray Spectroscopy (EDS) Analysis:

- Non-destructive: EDS analysis is a non-destructive analytical technique, which means that the sample does not need to be destroyed during analysis.

- High sensitivity: EDS analysis has a high sensitivity for detecting elements, allowing for the detection of trace elements in a sample.

- Fast analysis: EDS analysis is a relatively fast technique and can provide results in a matter of minutes.

- Elemental mapping: EDS analysis can provide elemental maps of a sample, which can be used to visualize the distribution of elements across a sample.

- Versatile: EDS analysis can be used to analyze a wide range of materials, including metals, ceramics, polymers, and semiconductors.

- Easy to use: EDS analysis is relatively easy to use, with minimal sample preparation required.

Limitations of Energy Dispersive X-ray Spectroscopy (EDS) Analysis:

- Limited spatial resolution: EDS analysis has limited spatial resolution, which means that it cannot be used to analyze features smaller than a few micrometers.

- Quantification limitations: EDS analysis has limitations in the quantification of elements in a sample, particularly when it comes to light elements, such as carbon.

- Surface analysis: EDS analysis is primarily a surface analysis technique, which means that it may not be suitable for analyzing the bulk composition of a sample.

- Sample preparation: EDS analysis requires the sample to be conductive, which may require coating with a conductive material, and the sample must also be thin enough to allow X-rays to pass through.

- Elemental interference: EDS analysis can be affected by elemental interference, where the presence of one element in a sample can affect the detection of another element.